Technical Insight

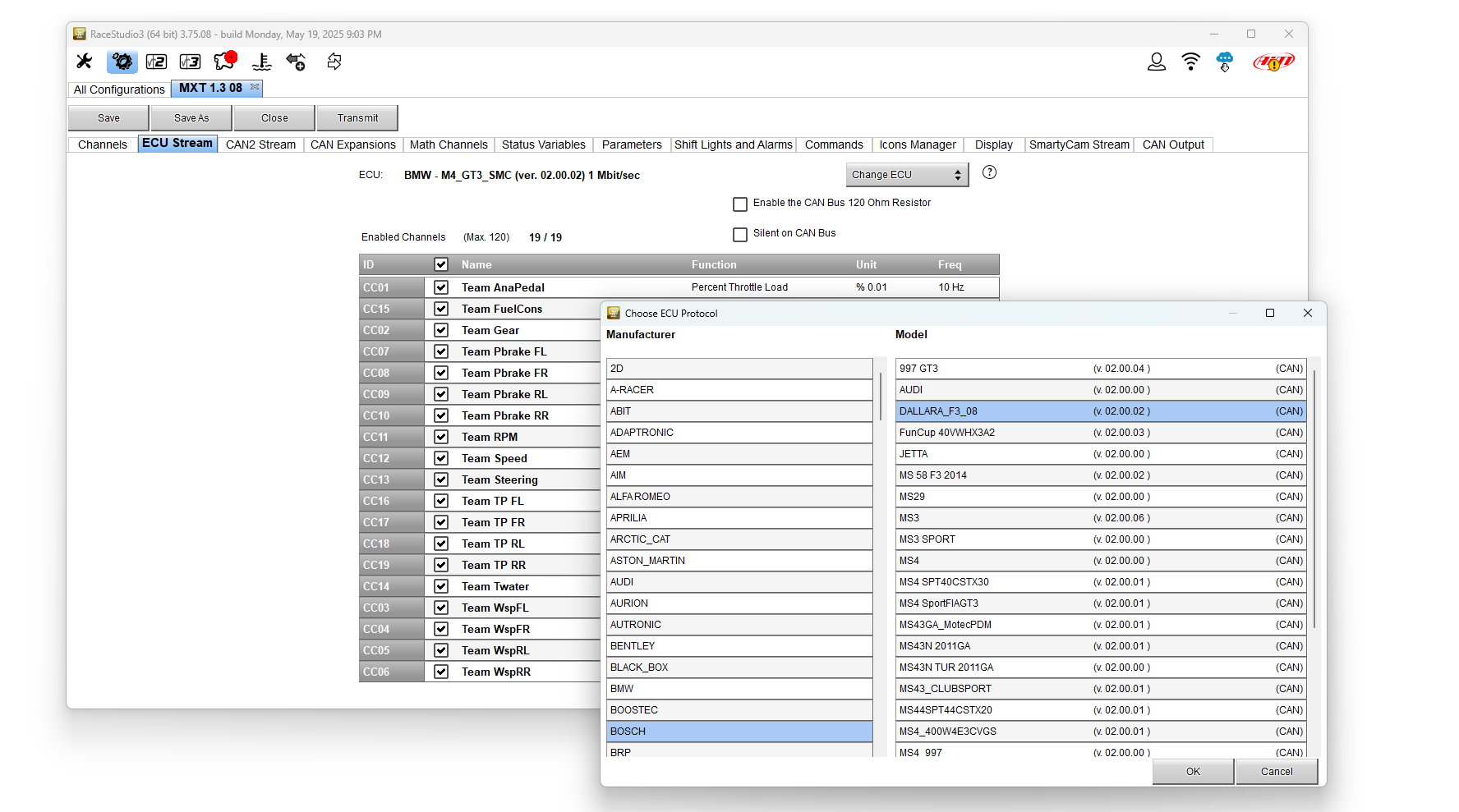

ECU connection

AiM systems acquire data from the ECU of your vehicle. The list of available ECU drivers, constantly updated and upgraded, includes 2,000 + different ECUs, either Stock and Racing; they are sorted by manufacturer/vehicle model: for each ECU you find the proprietary communication protocols, including the standard OBDII ones. From a hardware point of view, AiM systems manage the following data lines: CAN, RS232 and K-Line.

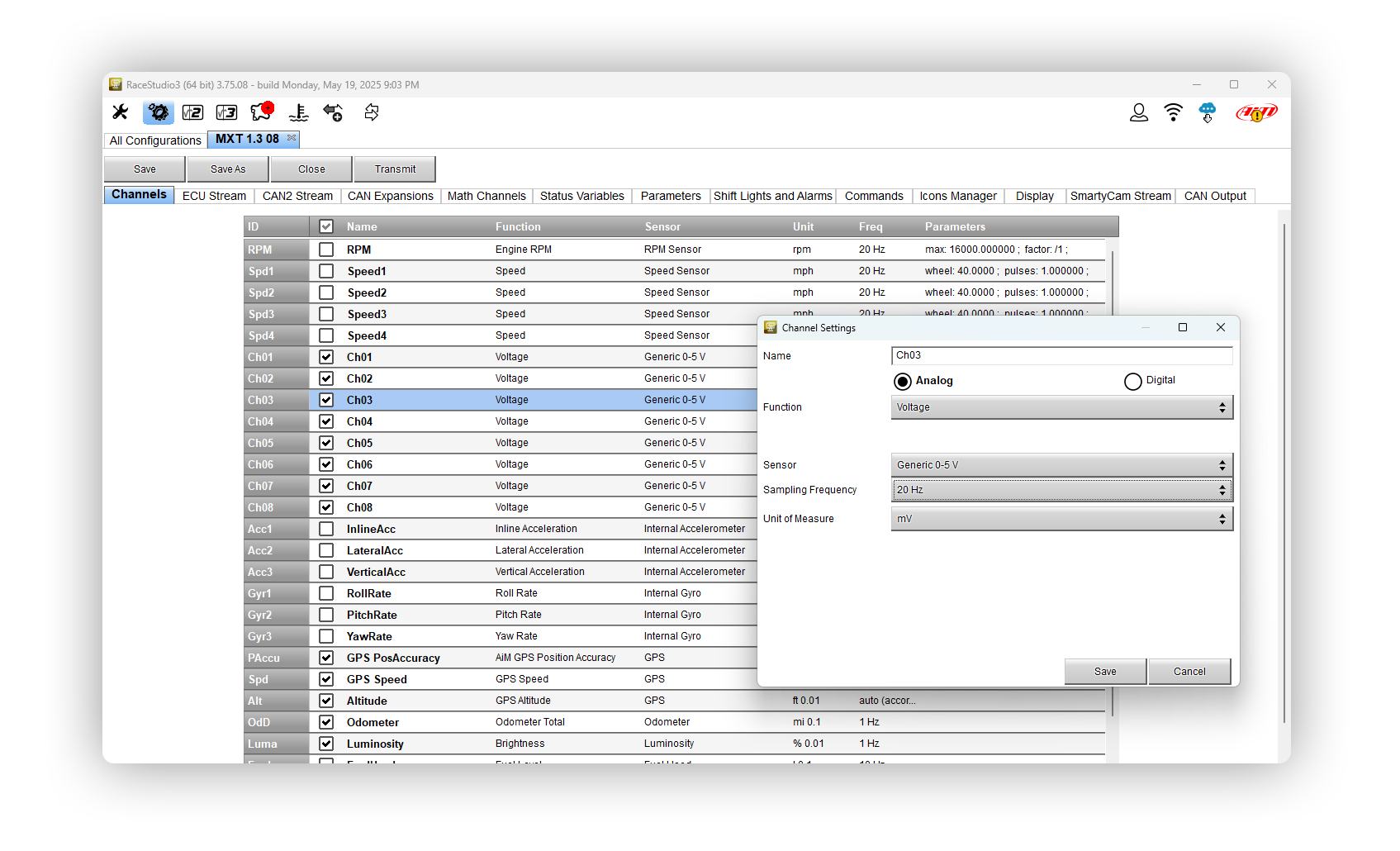

Analog/digital inputs

AiM systems analog inputs are recorded up to 1,000 times per second each. You can connect and monitor all kinds of sensors, like:

☑️Ratiometric potentiometers

☑️Pressure sensors

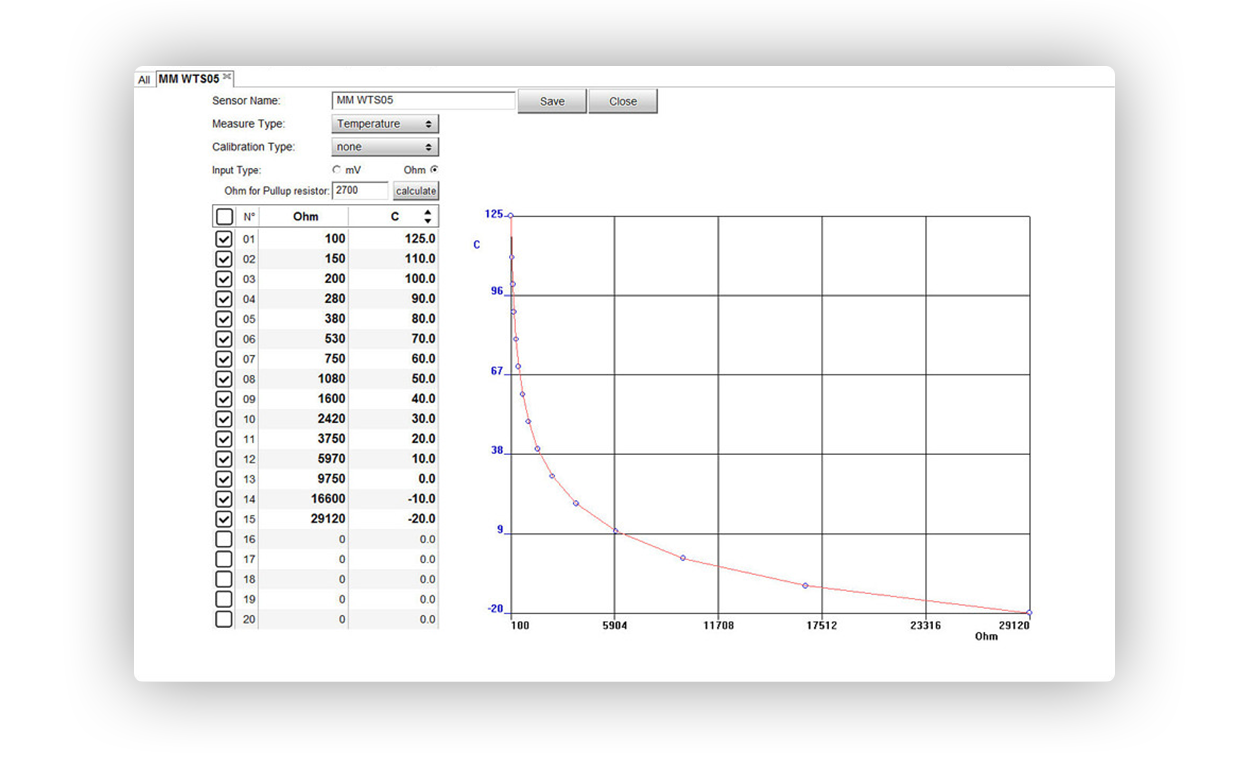

☑️Thermo-resistances

☑️K-type thermocouples

... and many others, all your custom sensors included.

AiM systems also feature digital inputs:

☑️Speed signals

From the ECU, from the GPS and from the wheel sensors.

☑️ RPM

From the ECU or from a digital input connected to a square wave signal (8 to 50 V) or to a low voltage (from 150 to 400 V) of the coil.

☑️Lap signal

Lap and split times are sampled by the GPS or via optical receiver/transmitter.

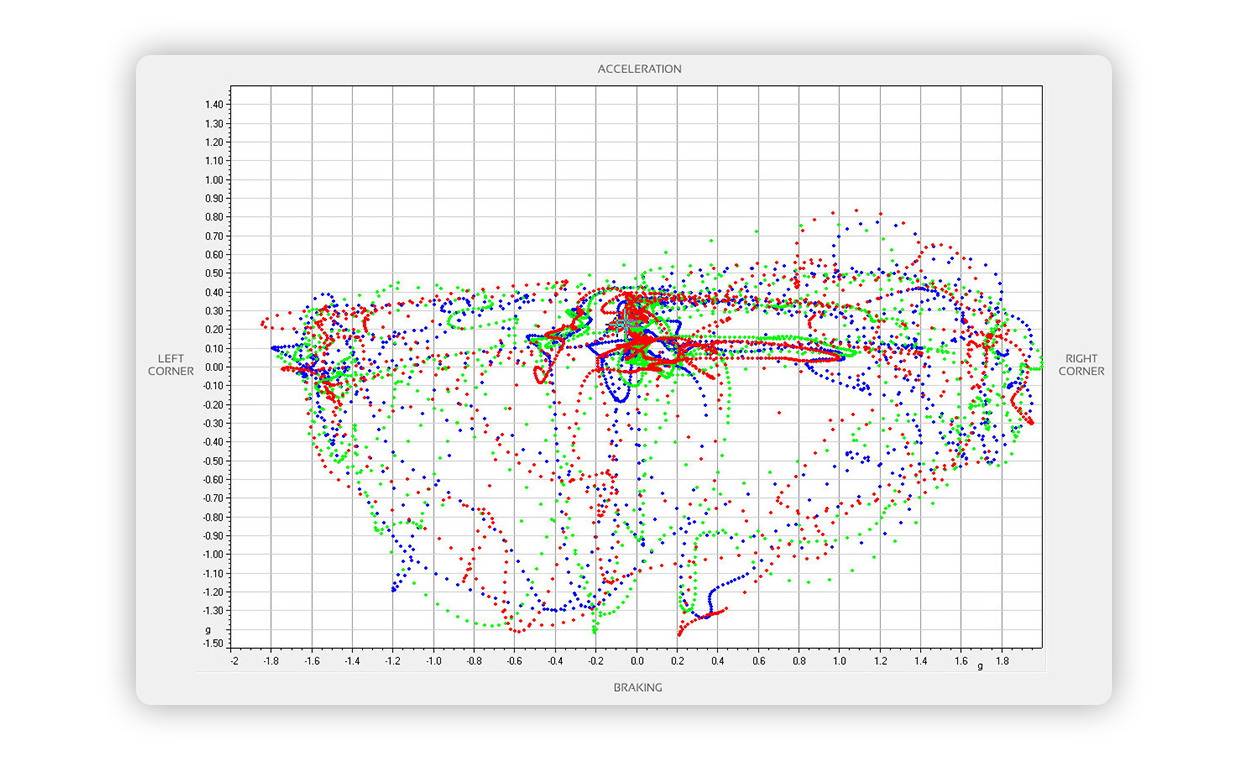

Inertial platform

The internal three-axial accelerometer, the gyroscope and the magnetometer provide the AiM systems a very powerful array of information. These force and motion sensors enable you to quantify the dynamic characteristics of your vehicle. Measuring acceleration forces and gyro rates can assist in determining how to improve your vehicle performances.

The graphic aside shows three laps run on the same circuit, based on the G-force data acquired by the internal three-axial accelerometer and the gyroscope: on the right and left side, the grapich shows the lateral acceleration the vehicle could stand while it was cornering (almost 2G reached on both sides). When it comes about the longitudinal acceleration, according to the graphic, the vehicle generates much more pression while it’s braking (down side of the graphic) than when it’s accelerating.

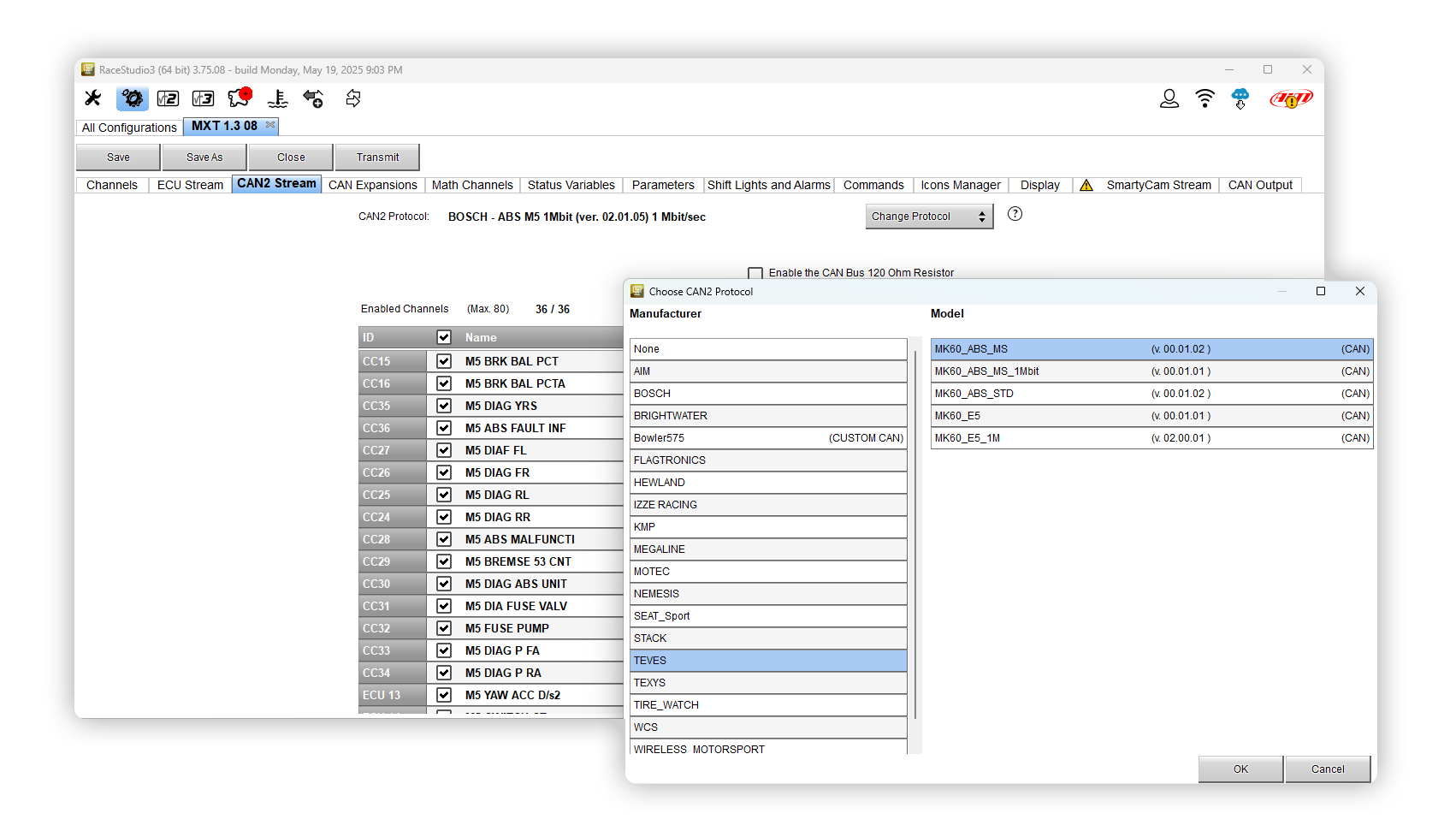

Second CAN

An innovative AiM systems feature is its CAN2 line, managing data coming from your additional modules

(i.e. ABS, traction control, infrared temperature sensors and more...).

This feature meets the requirements of a growing number of racers, as the use of additional modules is becoming quite common in a number of series.

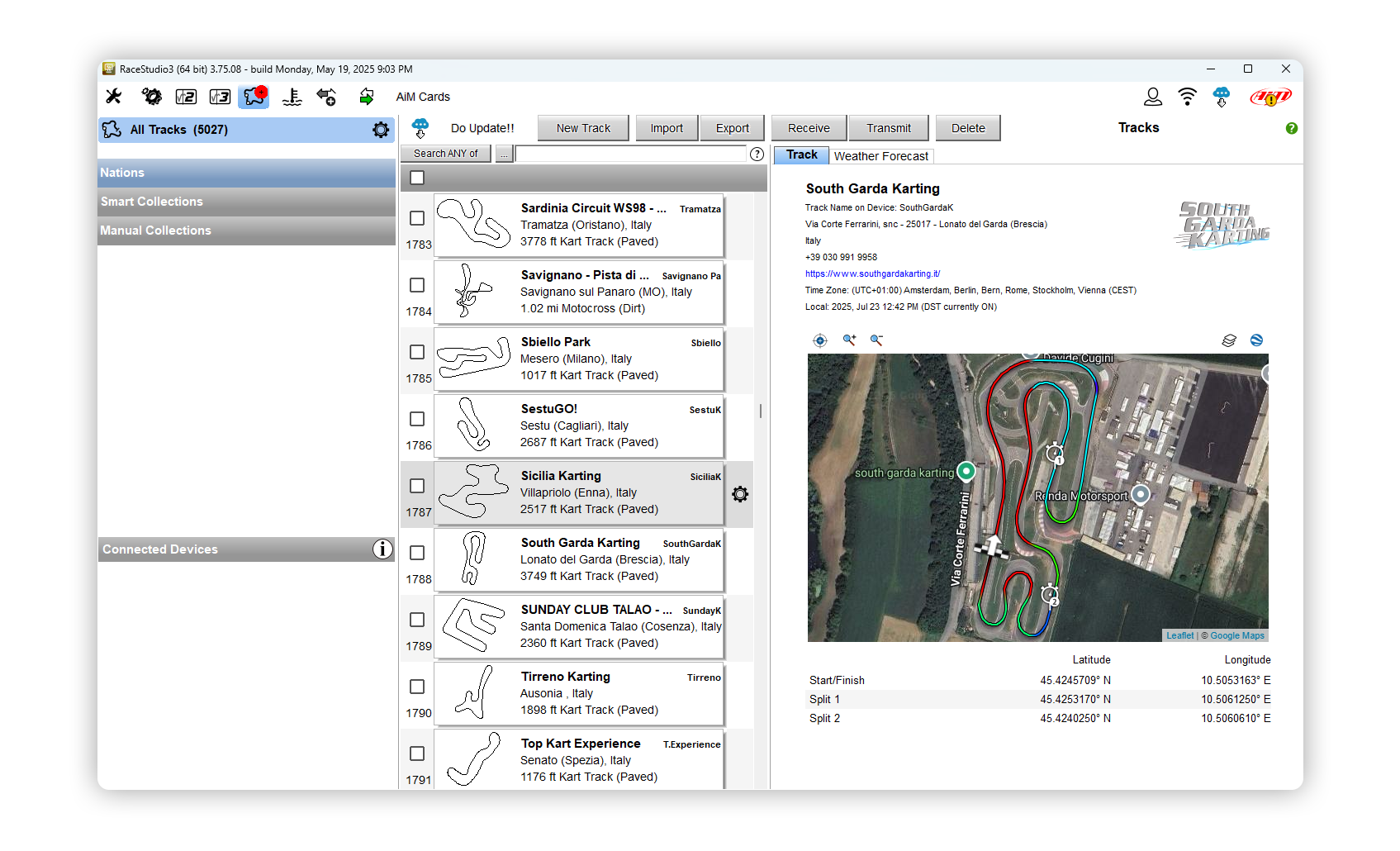

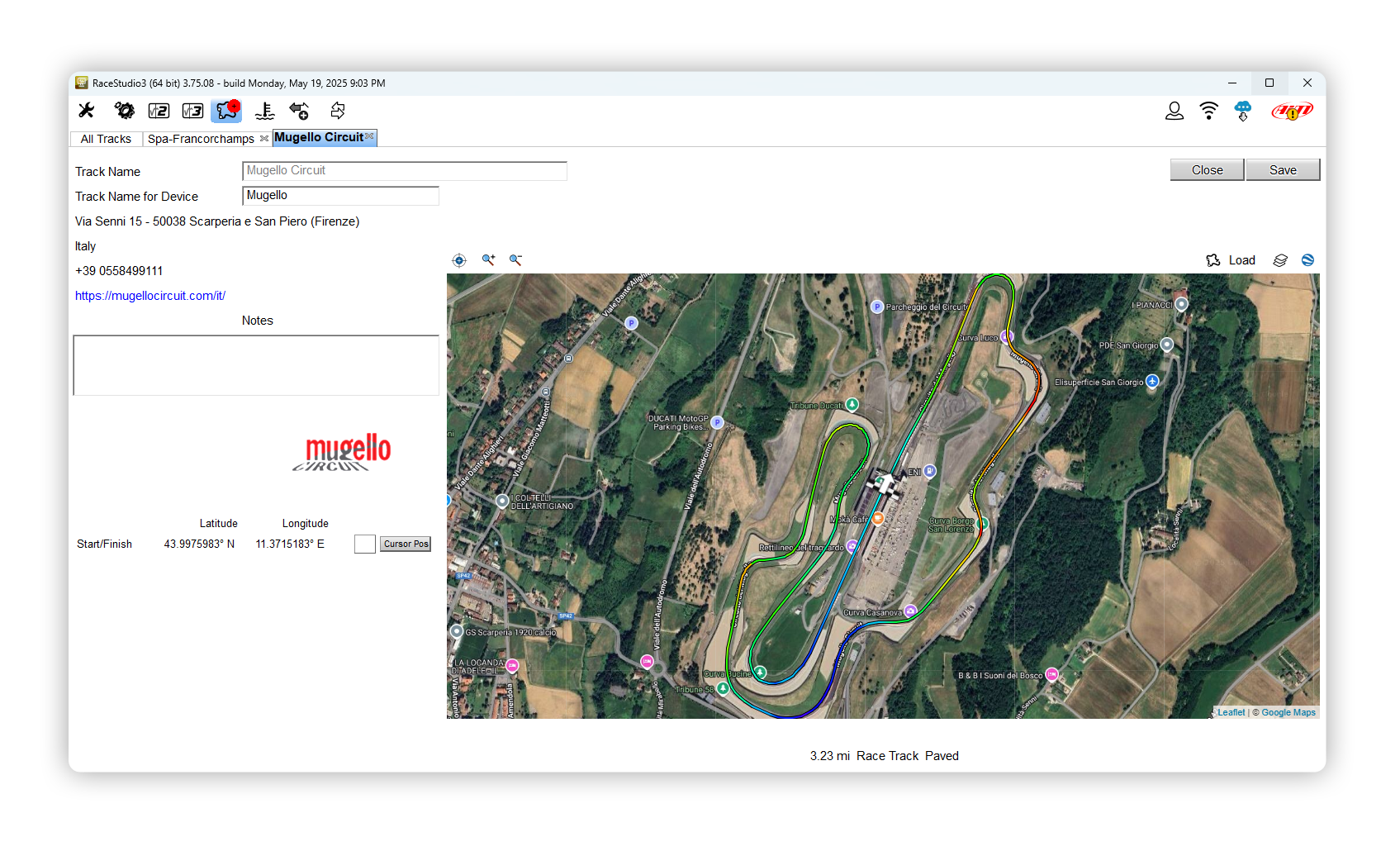

To calculate these data the system needs to know the start/finish line coordinates of the racetrack you are racing on.

MX Series comes with a long list of the world main tracks, constantly updated by our technicians and automatically loaded to your PC when you run RaceStudio 3 software and a connection to the Internet is available.

Track selection mode

AUTOMATIC

MX Series automatically recognizes the track you are running on, loads the start/finish line and the possible splits coordinates and calculates lap and split times without optical/magnetic receiver. This is the best mode in most cases.

MANUAL

Allows to manually select the track from the internal database. This mode is to be preferred when multiple track configurations are available nearby. In this case MX Series would anyway recognize the track but would need at least one complete track lap.

You can scroll the list of available tracks choosing among these options:

☑️ nearest – shows only tracks in a 10 km distance

☑️ all – shows all tracks stored in the system in alphabetical order

☑️ custom – shows only the tracks you have previously created with RaceStudio 3 software